100% Hemp, Hemp, Hemp/Cotton, Sustainable Fashion

How Is Hemp Processed To Make Bags?

Various sources of natural fabrics such as cotton, wool, and silk have grave implications on the environment during cultivation, production, and disposal. Hemp is a great alternative to these fabrics. It is often considered to be the most sustainable fabric. Its high yield, low water footprint, durability, resistance, and unspoiled processing practices are the reasons why. Today hemp is used to make a variety of commercial and industrial products including rope, textiles, clothing, shoes, food, paper, bioplastics, insulation, and biofuel. By understanding how hemp fabric is produced, we can help you make up your mind about whether it is as sustainable as people swear by.

What is hemp fabric?

Hemp is a distinct variety of plant species Cannabis sativa. Hemp fabric is a type of textile made using fibres from the stalk of this plant. The plant can grow anywhere from 1.2 to 4.5 meters (4-15 ft) in height and around 2 cm (0.75 inches) in diameter. It is recognized for its extraordinarily tensile and durable textile fibres as well as an immensely beneficial crop. Originated in Central Asia, hemp from the Himalayan regions of Nepal is widely used in making sustainable and eco-friendly clothing. Hemp is one of the leading fabrics in the handmade clothing industry in Nepal.

Hemp has a deep-rooted history in Nepal. For centuries, people grew cannabis to harvest its leaves and fibres. The weaved fibre was used to make everything from paper to fleeces. The Nepali word for fabrics made from hemp stem fibre is ‘Bhangra’. Bhangra is mostly made in the western Himalayan regions of Nepal namely Darchula, Bajhang, Bajura, Dailkeh, Jajakot, Rolpa, and Rukum. In the context of well-established traditional practices of making hemp fabric, Nepali Bhangra is a high-quality fabric. It is how these fabrics are made that makes them much more popular and ethical among fashion-conscious people.

Although the traditional methods are a little different from industrial processing, the basic concept is the same.

How is hemp fabric made?

Cultivation:

As a crop, hemp grows well in a mild climate with high humidity. In Nepal, hemp cultivation takes place in altitudes between 1500 to 3000 meters. Sowing occurs during early spring. The hot weather is ideal for hemp seedlings to begin germinating. Cultivating hemp doesn’t require a lot of lands. It gets crowded with about 30 plants per square foot area. But this process minimizes leaf growth and maximizes fibre yield. The seedlings will begin to sprout within 5 days of sowing.

Growing hemp:

Hemp is a pretty low-maintenance crop. It doesn’t require a lot of water and repels pests naturally. Also because hemp plants grow densely, there is less risk of pests and unwanted weeds. Hence, there is no need to use pesticides and herbicides. This means hemp cultivation causes minimum damage to the soil, doesn’t require much water, and grows well in the next growing season. Hemp is as a result, much more sustainable, eco-friendly, and organic than other plants.

Harvesting:

When the hemp plant flowers and seeds start to set, the plant is said to have reached maturity. At this point, the hemp fibres are at their strongest. So, it is ready to harvest in this period. Generally speaking, the harvesting season is in early winter (October to December). Each plant is cut from the root using a sickle. The plant is then made ready to process fibre.

Retting:

Retting is the process of softening the coarse hemp stalk to loosen the fibres. Depending upon the weather, there are two ways to ret hemp stalks.

- Dry retting: the stalks are laid in the field out in the open to dry under the Sun. Most of the nutrients extracted by the plant return to the soil as the leaves decompose.

- Wet retting: In wet retting, the hemp stalks are soaked in water (in a tank, pound, or flowing water bodies) for at least a week. The water helps break down the unwanted cellular tissues binding the fiber.

Retting also clears away any dust, insects, and other contaminants from the hemp stalks.

Breaking:

Next, these softened help stalks are broken using breakers, or hammermill to separate the fibrous section from its woody core.

The hemp fibres so obtained are beaten with a long paddle. Beating the fibres starts to release them from the stalk. Then, you let the fibres dry in the sun for another three to five days after coating them with soft clay. The final step in preparing the hemp fibre is to twist the strands of fibres. This creates a bundle called roving, which is easy to spin.

Spinning:

The hemp roving is now ready to pass through a spinning machine to produce hemp yarn. Traditionally, the fibres are wetter to make even softer yarn. At this stage, the same processes that are used to make other fabrics are used to make hemp fabric. Thus obtained yarn is woven into tight fabrics, and these fabrics may be used for a variety of consumer purposes like hats, bags, and other articles of clothing.

Why should you choose Hemp products?

Hemp fibres are tested for tensile strength, fineness (fibre diameter), moisture content, etc. at every stage of production. Hence, hemp fabric is highly popular in clothing since it is resistant to wear and tear. Unlike cotton apparel, which falls apart, warp, or shrinks after a few washes, hemp items retain their shape and integrity for years and years. Its high absorbability and durability make it a great substance to make bags, towels, blankets, and duvets with.

Read: Why Choose Hemp Bags?

Hemp is also one of the least waste-producing fabrics. During fibre processing, the core fibre is saved and usually used to make paper, horse bedding, or construction materials. Even the dirt and small chips of the core are used as a high nutrient soil additive.

Hemp bags are known for being strong, durable, and most importantly sustainable. They cause no pollution since they emit no CO2. The hemp plant is capable of capturing CO2 and turning it into oxygen.

100% hemp products are fully compostable and bio-degradable. Where it takes an average plastic bottle roughly 450 years to decompose, hemp products are decomposed in 6 months in the proper environment. Hemp is also a non-water-intensive crop which makes it a more sustainable choice than cotton. Furthermore, hemp fibre is ten times stronger than cotton.

The very obvious bottom line here is that 100% hemp products are fully biodegradable. At every stage of production (sowing, growing, harvesting, processing, and disposing of), hemp is exceptionally more sustainable than conventional cotton. Hemp products are strong, durable, as well as attractive. Locally made hemp bags and clothing in Nepal are organic and support skilled workers in rural areas. All these reasons make hemp worthy a shot in your daily life. Purchase 100% hemp products grown, processed and made in Nepal from our website. Making conscious decisions is a choice and it is high time we started making a change to protect our planet.

Check out the range of bags made of Himalayan Hemp available at our website himalayanmerch.com:

-

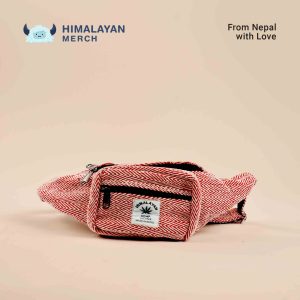

Hemp Fanny Pack$ 15.00

Hemp Fanny Pack$ 15.00 -

Hemp Tobacco Purse$ 10.00

Hemp Tobacco Purse$ 10.00 -

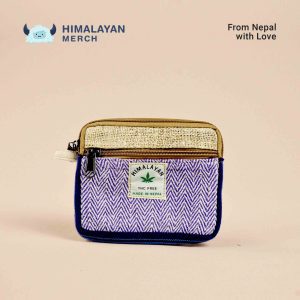

Hemp Wallet$ 6.00

Hemp Wallet$ 6.00 -

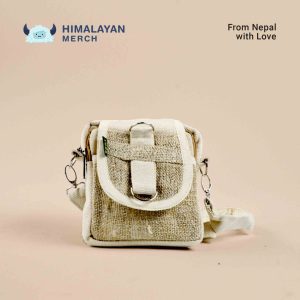

Hemp Passport Bag$ 22.00

Hemp Passport Bag$ 22.00 -

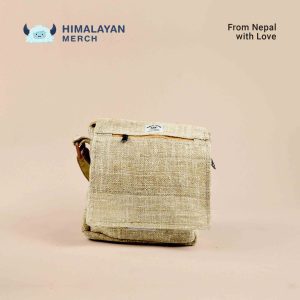

Pure Hemp Side Bag$ 22.00

Pure Hemp Side Bag$ 22.00 -

Buttoned Hemp Bag Pack$ 35.00

Buttoned Hemp Bag Pack$ 35.00 -

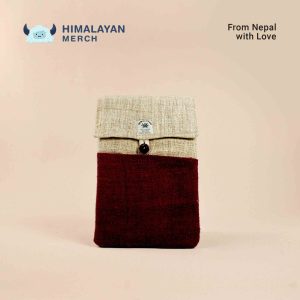

Hemp Laptop Sleeve$ 28.00

Hemp Laptop Sleeve$ 28.00 -

Hemp Laptop Bag | Laptop Case$ 20.00

Hemp Laptop Bag | Laptop Case$ 20.00 -

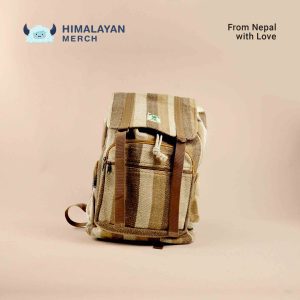

Hemp RuckSack$ 40.00

Hemp RuckSack$ 40.00